INSTRUCTIONS:

Sunday, October 31, 2021

MoBeam: Grbl Startup

Saturday, October 30, 2021

MoBeam: VigoWorks Setup & Operation

VigoWorks

Documentation

The documentation describes the functions but not in enough detail to understand how they impact engraving and cutting quality.

Notes:

- Many modes of the software are single-threaded. Ensure that windows are closed and you exit active modes before trying to make settings changes. Sometimes the interface does not intuitively tell you to change modes.

- I do not see any way to engrave and cut at the same time. There is no way to mark image features as cut lines.

- There is a way to design text string but there is no image or vector editing.

- You supposedly can upload Gcode and Images.

- I have experienced intermittent crashes and the controller needed to be power cycled.

- No way to add stuff to the gallery?

The Effects of Settings on Imaging

Offline Imaging

Default file on SD card

- Name: sd_default.nc

- One file is allowed and must be named with .nc extension

- Verify: Uploaded and overwritten from VigoWorks?

Enjoy,

Comments are always welcome.

Please, consider using the donate button on the sidebar if you found this post valuable!

Don

MoBeam: Positional Accuracy

Movement Scale

|

| Settings I changed |

----------

Comments are always welcome.

Please, consider using the donate button on the sidebar if you found this post valuable!

Don

MoBeam: Software/Firmware Updates

Software Update

VigoWorks 3.25_2110203

- New version: VigoWorks_v3.25.exe

Firmware Update

- New Firmware: Firmware_for_328p_v3.12_20211023

OTA Update?

Upload Tools

There is also an upload tool under "Driver_And_FwUploadTools" but I am confident how to use it and do not want to brick my controller.Using the Upload Tools

Trials of a Poorly Supported Controller

MoBeam: Laser Focus

Laser Module in MOBeam

- 30820

- 30610

Focus

If you assume the VG-L7X manual had the wrong units for focus, i.e CM vs MM.

Then I have a G8 lens in my unit? Is this a coincidence?

The smallest beam spot also explains why the dot looks rectangular (laser diodes do not operate in TEM00).

However, at the focal point, the intense area of the beam is round.

https://laserpointerforums.com/threads/there-is-something-wrong-with-my-beam-spot.59400/

Finding The Focal Point

Focusing Techniques

The Empirically Derived MoBeam Focal Distance

Focus Using a USB Microscope

Test Setup

- Make a target by painting a substrate with flat black paint. I used a round steel medallion. A black surface makes it easier to see the most intense part of the beam.

- Put on your laser safety glasses

- In Vigoworks turn on the "weak beam"

- Place the microscope on its stand in front of the laser module focussed on the beam.

Adjustment

- Adjust the entire module up/down to get the smallest round spot.

- With the module fixed in position adjust the lens until the smallest round spot is achieved.

Depth of Focus Measurement

Focusing For Cutting vs Engraving

MoBeam: Text Engraving

Engraving Text

Aluminum Techniques

Engraving Painted Aluminum Vigotec VG-L7 20W Laser Engraver

- Speed: 750 - 1250 mm/min

- Power: 90-95%

- 13 dots/mm

- Pause: 45ms

|

| From YouTube Video |

From the Manual

In the right parameter control area of the software,- Select Binary-Line engraving mode.

- Adjust the size of the engraving picture.

- Adjust the line engraving speed value to 3000,

- Laser power value to 90%,

- Line or point density DPM value to 6

1st Lettering Experiment #1

Wood

|

| No horizontal patterns |

- Speed: ?? mm/min

- Power: 4%

- 5 dots/mm

- Pause: 50 ms

Painted Plastic

|

| Horizontal patterns, scan or settings error? |

Painted Steel

| |

|

- Speed: ??? mm/min

- Power: 80%

- 5 dots/mm

- Pause: 50ms

Test #2

Calculate the resolution @ 5dots/mm:

Calculate the resolution @ 13dots/mm:

Sunday, October 17, 2021

MoBeam: Focus on Safety

Safety

- Protection from the beam in normal operation

- Protection from the beam if the machine is lifted off the surface

- Interlocks on any covers that open horizontally placed relative to the laser.

Head-Sheild

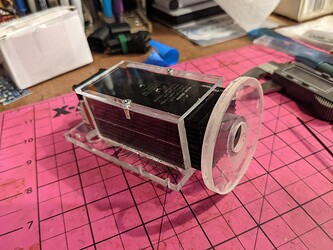

My current approach is to use a light shield under the diode head made of filter material. The body of the machine may be made from clear acrylic. I do not think the body needs to use filtered materials when combined with the head-shield.

Caution: I have not tested this concept. It seems logical that the placement of the shield [close to the surface] would make a dangerous reflection unlikely. Also, this approach

is being used by others that I judge to know what they are doing.

JTech

JTech is one of the best sources I have found on Laser Diode safety, engraving, cutting, and technique.

Sheild Material

- Practical FL

- Practical DOF

250nm to 520nm Laser Shielding – 12″ x 12″

The shield may also serve as the focal adjuster.

Lift Interlocks

To further make this safe I also plan to have the means to turn off the laser if the machine is lifted off the surface. You could also accomplish this with a full enclosure but I am trying to make MoBeam capable of laying on top of various thicknesses of materials, mostly wood. Therefore the bottom of mine will be open.

----------

Enjoy,

Comments are always welcome.

Please, consider using the donate button on the sidebar if you found this post valuable!