The Not So Stable Carriage

After the assembly of my VG-7x I noticed significant play in the carriage in both the X & Y-axis.

Laser diodes are sensitive to operation at the correct focal point. IMO movement of this nature would affect the engraving quality. So I set out to remove that error. The video below shows the large "slop" in the stock carriage.

Adding Eccentric Spacers

Inspection of the carriage revealed that there was no mechanism for adjustment of the wheels with the V-slot. The design apparently expected the tire mounting hole placement to be accurate enough to make a tight fit.

There is a small amount of play in the axle bolt holes due to the hole tolerances. There is also some slight movement possible since the upper plates holes (5.9mm) are slightly larger than the lower plate holes (5.5mm). I don't know if these hole sizes are intentional or just an artifact of fabrication. In any case, they do not allow enough adjustment.

So I set out to learn how CNC machines are designed to allow adjustment of the carriage tires to the V-slot interface. I already had a hint since I built a CNC router using V-slot extrusions.

It's pretty conventional for these carriages to use eccentric spacers in one set of tire axles as a means of adjusting the play out of a V-slot carriage. The eccentric spacers allow the tire axle to be adjusted toward and away from the V-slot by rotating the spacer.

My plan was to make a cloned set of carriage plates and redrill one set of holes to accept two eccentric spacers. The cloned plates would allow me to try out the concept without damaging the stock parts.

I found the eccentric spacers on

amazon.

Cloned Plates

I removed and traced the plates onto the graph paper. While I had the plates out I started dimensioning the part in anticipation of later doing a CAD version. Full-scale PDFs of those are attached. I may or may not create F360 designs depending on community interest. In the meantime, I find it quicker to make 1 proto part set by hand and I did so.

The two stock plates were used as templates and their outline was scribed on 1/4 plastic (Home Depot).

I simplified the outline into a rectangle before drilling the hole features using the stock parts as a template. To accurately drill the holes I double back-taped the stock plates to the proto material (plastic) and drilled through both.

I reassembled the carriage using the cloned parts to check that everything fit and it did. While doing this I realized that I only need the bottom plate as the top plate is not part of the adjustment schema. I just need to ensure that the top plate did not interfere with the bottom plate's axle adjustment.

I disassembled the carriage again and redrilled two holes (7mm) to accept the eccentric bushings. The bushing was a tight fit and I needed to tap them in with a hammer.

Note: there is a feature on the bushings that indicates the smallest adjustment location.

|

| Cloned Plates |

Modified Carriage

The photos below make the assembly self-explanatory so I will only give the highlights.

Everything fit properly. I actually did not need to adjust the spacers at the smallest spacing the eccentric spacers did their job and now the carriage rolls smoothly with no play and minimal friction. The acid test is to ensure that the carriage is not too tight for the steppers to drive.

I worried that the top plate would interfere with and perhaps bind the axles. They did not because I assembled, adjusted, and tightened the carriage without the top plate and then installed the top plate with the thumbscrews.

I also was aware that the cloned plates were a bit thicker than the stock plates and expected the axles to be too short. In the end, I used the cloned bottom plate and the stock top plate. That combination left just enough room for the top thumb screws to be installed.

I also wondered why the stock plates had such fancy features (curves). I still don't know why as the simple rectangles have worked fine ... so far. That is with the exception of the lower right of the bottom plate. A corner needed to be cut away to allow the wiring harness to reach at the carriages X extreme.

|

| Top And Bottom Cloned Plates |

|

| Top Cloned Plate (not used) |

|

| Cloned Bottom Plate |

|

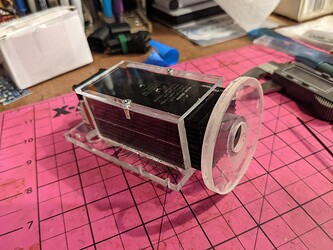

| Assembled Carriage. Note the cutaway corner |

|

| Eccentric Spacer |

|

| Fully Assembled Modified Carriage |

Assembling the Tires and Axles

It's important to assemble the axles, spacers, and tires in the correct order which from bottom to top is:

- Axle

- Lower plate

- Eccentric Spacer

- Tire

- A small stock plastic spacer

- Top Plate

- Thumbscrew

Note: The Al spacer that comes with the eccentric kit and the large stock nylon spacer are not used.

Documents

This Document Contains 1:1 sketches of the bottom and top plate so that you can fabricate your own prototype bottom plate. So far it seems the top plate can be used as-is and a clone is unnecessary. You could also just drill the featured eccentric spacer holes on the stock bottom plate. That said I would wait until more testing is completed before hacking the stock plate.

Conclusion

The new carriage configuration has reduced the "play" and the carriage is substantially "stiffer". I have yet to test it in operation..... new problems may appear.

This is not an expensive change ($2.20 for 2 spacers) and I am surprised that Vigotec didn't include this in their design. Then again perhaps there is something I missed... time will tell.

If you are having a problem with your FG-7X image quality and or holding FL, especially at higher speeds (vibration) you should consider this modification.

Enjoy and comment,

Don