Installing a Non-stock LPS in the K40

Better quality and higher power LPS's can be obtained from companies like Cloud Ray.

The K40 can be modified to accommodate this kind of supply if:

- A 24vdc supply is added

- The K40 is rewired to accommodate the new supply

Arguably this is a lot of change for a K40 but the machine will be better off because you will end up with:

- Better quality LPS

- Higher power 24V supply

Alternate LPS type

This type of supply is typically compatible with these instructions. Check the signals on the new supply to see if they match the schematic below.

The connectors typically look something like this:

Adding the 24VDC supply

You will have to purchase a 24VDC supply and mount it somewhere. The schematic below shows how it is wired in but not how to mount it. The mounting will depend on the actual supply you buy.

The stock 24vdc supply only handles about 1 amp @24vdc. So purchase a supply with more than this capacity.

Here is a supply with enough capacity to power your K40 even if you upgrade the controller later on.

Adding the alternate LPS

The schematic below is for a HY-T50 LPS but any supply with the same signals as shown in the schematic will work.

Remove and replace the stock supply

- Unplug the K40

- Unscrew the stock supply

- Unplug the input connectors (either green or white)

- Cut the HV lead on the back of the stock supply leaving approximately a 4" pigtail so the stock supply can be used elsewhere.

- Procure a high voltage connector and add it both to the new LPS and the HV lead in the machine. Here is a good one: high voltage connector. Your supply may come with one.

- Mount the new supply to the floor within reach of the wiring harness and the HV cable.

Wire in the new supply

Using the schematic below modify the wiring harness to accommodate the new supply. You may have to cut off the existing connectors (white) to accommodate the new connectors types which typically are the green screw terminal type.

Ideally use pin crimps for better reliability. Here are the pins with crimp tool: Wire terminal connection kit.

Power on and test

This is a basic test procedure to verify your wiring.

- Unplug all the green connectors

- With a DVM on the ohms scale check the connections to the laser switch and laser test switches.

- The WP connection should read 0ohms to gnd when the Laser Switch is pushed.

- The TH connection should read 0 ohms to 5V when the Laser Test Switch is pushed.

- Plug in the machine and power on [all connectors are unplugged]

- On the 3 pin AC plug verify the correct AC voltage with a DVM. CAUTION: Be careful not to short out the pins with your meter.

- Power off the machine

- Plug in the 3 pin AC connector

- Plug in the remaining green connectors

- Power on the machine

- With a meter verify the voltages on the LPS connectors are correct per the schematic.

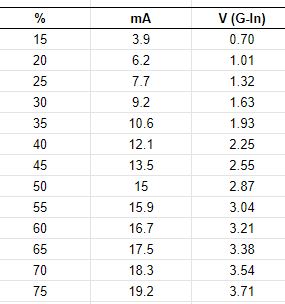

- Rotate the pot, the IN pins voltage, when measured to grnd, should vary from 0-5vdc

- The TH pin should read 5vdc when the Laser Test Switch is pressed

- The WP pin should read 0vdc when the Laser Switch is pressed.

Please Donate!

If this post helped you solve a problem, saved you time or was otherwise useful consider donating. Use the link in the upper right of the site.

Donations fund some of the expense of tools and materials for my shop and lab so I can bring you more content like this.

Donations fund some of the expense of tools and materials for my shop and lab so I can bring you more content like this.

Also let me know if there is other content you would like to see me explore!

_____

Thanks and please comment

Don